BTI has the latest technology for producing machined structures, sintered with angulation correction or with 3D printing.

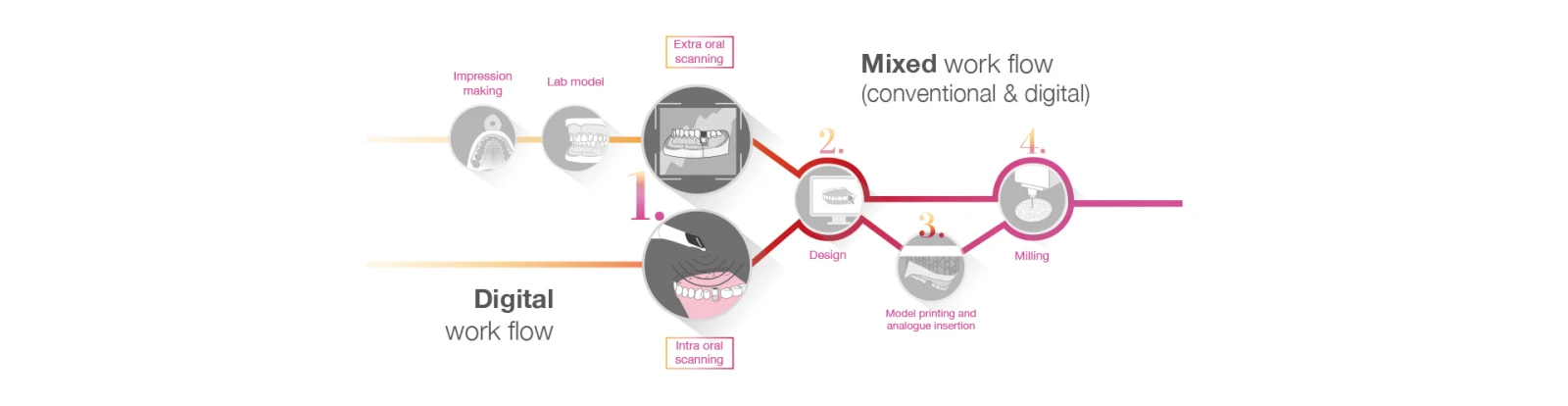

< Oral implantologyBTI, through the HTL Dental Laboratory specialised in digital flows, provides dental professionals with CAD/CAM design and production solutions using intraoral scans or laboratory models, in several materials such as Titanium, cobalt-chrome, zirconium, PMMA, lithium disilicate, PEEK, eMax or composite.

There are several technologies nowadays, but we'll focus on the two main ones, even though they are very different: subtraction and addition.

CAD/CAM by subtraction: commonly known as drilling or micro-drilling, is the elimination of material from a solid block, using a drilling technique.

CAD/CAM by addition: commonly known as sintering or sinter-drilling, is the fusion of thin layers of metallic dust.

HTL, a BTI Group company, has optimised the material and all the manufacturing processes of the unloading splints, from the initial design to their manufacture, to protect teeth and prosthetic restorations, providing comfort and durability to guarantee patient satisfaction.