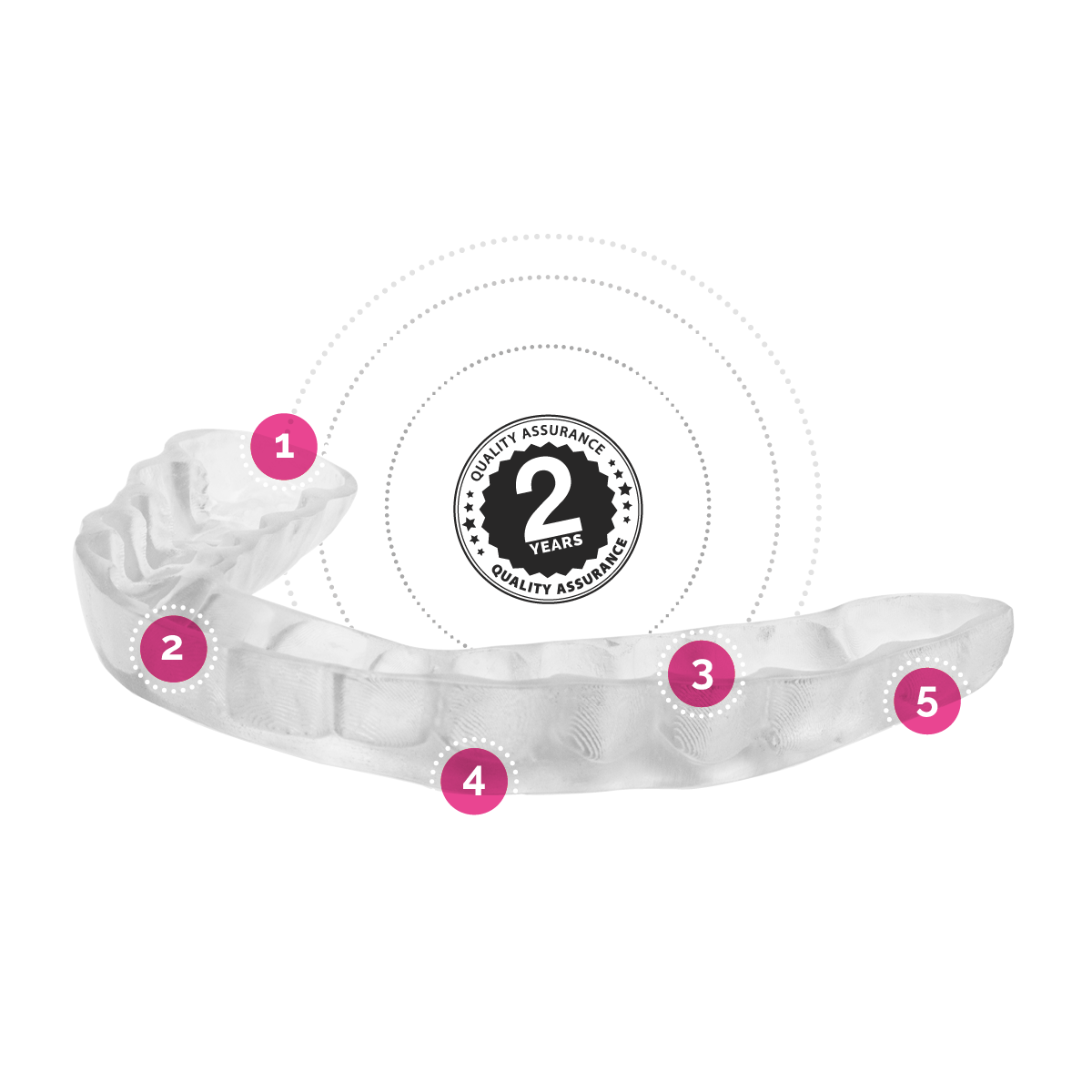

HTL, a BTI Group company, has optimised the material and all the manufacturing processes of the unloading splints, from the initial design to their manufacture, to protect teeth and prosthetic restorations, providing comfort and durability to guarantee patient satisfaction.

From now on it is possible to treat temporomandibular joint (TMJ) pathologies and disorders associated with the bite in a more reliable, safe and successful way. Clinical indications: temporomandibular disorders (TMD), prevention of bruxism complications and protection for restorative treatments.

Advantages

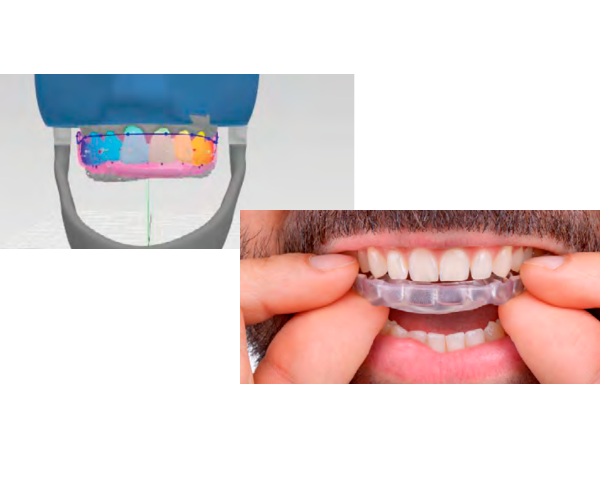

In-house design and manufacturing technology